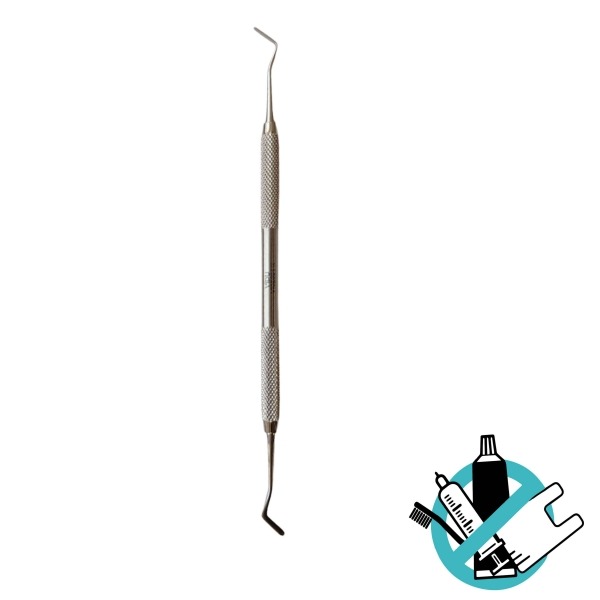

Anterior Composite Capacitor - VIDU

VIDU composite instrument:

- Plastic Neutral. Plastic footprint = 0 gr. *Certified by Gravity Wave..

- Filling instrument used for easy contouring and placement of composite resins with the help of its non-stick coating.

- The tip surface allows for even application and shaping of the composite during restorative procedures.

- It has a solid C6 stainless steel handle.

Similar product recommended:

- Nº 1 in Dental restoration instruments

- Nº 937 in all Dentaltix

You have 15 days for free return.

You have 15 days for free return.VIDU composite instrument:

- Plastic Neutral. Plastic footprint = 0 gr. *Certified by Gravity Wave..

- Filling instrument used for easy contouring and placement of composite resins with the help of its non-stick coating.

- The tip surface allows for even application and shaping of the composite during restorative procedures.

- It has a solid C6 stainless steel handle.

Similar product recommended:

Bought together usually

Description

The Anterior Composite Condenser is an ergonomic, conventional and high quality instrument.

Features of Anterior Composite Capacitor:

- Filling instrument used for easy contouring and placement of composite resins with the help of its non-stick coating.

- The tip surface allows for even application and shaping of the composite during restorative procedures.

- It has a solid C6 stainless steel handle.

- Content: 1 unit.

COMPOSITE CONDENSER - PLASTIC NEUTRAL CERTIFIED - ZERO PLASTIC FOOTPRINT

The Composite Condenser is part of the specific hospital waste group IV, materials that cannot be recycled if not incinerated, for hygienic, sanitary and usage reasons it is difficult to find an alternative of another material. VIDU works to always offer the most responsible solution and, while maintaining the necessary hygienic qualities in the clinic, always seeks a balance between fair price and care for the planet.

Environmental Impact Gauges >> Plastic footprint of VIDU Composite Capacitor = 0 gr.

- Weight of plastic used = 10 gr.

- Weight of plastic collected = 10 gr.

- Type of collection: Normal.

- Location: Mediterranean Sea.

- Certified by Gravity Wave.

- Learn more.

LET'S BE PART OF THE CHANGE!

- Plastic Neutral. Certified by Gravity Wave.

- 100% recyclable packaging. Recyclable materials have been used in the packaging of the Composite Condenser, always guaranteeing the highest quality and hygiene conditions for the products.

- Fair price. By achieving a fair and reasonable price, we always seek to offer the least polluting and most easily recyclable solution possible, guaranteeing the highest quality and hygiene conditions for the products.

- Online distribution. The marketing of these products is carried out via the internet, thus avoiding unnecessary transport and contamination.

- Responsible consumption. Do not use more instruments than necessary!

How to manage the waste generated in the clinic with the use of the Composite Condenser?

- How to recycle instruments?

- How can the packaging of this product be easily recycled?

The instruments are sterilisable and multi-purpose products. Unfortunately, at the end of their useful life they cannot be recycled, as they are a product that must be incinerated and belong to group IV of sharps waste. VIDU is working on the development of alternatives and new recycling channels for waste generated in the clinic.

The packaging of the Composite Capacitor is made of cardboard and is recycled in the blue bin.

Where does the Composite Capacitor come from?

One of the brand's objectives is transparency, which is why the country of origin is always specified on the packaging of all products. It will vary from one product to another, always looking for the manufacturing conditions that ensure: Quality, sustainability and fair prices.

In this case, it is manufactured in China.

Questions and answers

There are no questions yet. Be the first to ask one!

You need to be logged in to ask questions. Login