SKU:

DTX2111-OS2004

Pro Expert 5: Dry and wet milling machine (5-axis) - Opera System

Brand: Opera System

Reference: DTX2111-OS2004

Mfr. reference: OS2004

Versatile Dry and Wet Machining Bur Machine:

- Equipped with 5 axes.

- It features an automatic 8-disc changer that takes care of material handling.

- The system chooses and inserts the appropriate disc for each restoration.

- Capable of non-stop machining without user intervention.

- Maximum precision, non-stop performance and reliability.

- High dust protection.

- Safeworking space .

- Light in the working chamber.

- Easy to place in any corner of the dental laboratory.

Request more information!

Contact us to receive personalized advice and budget.

Call +44 2036086214Versatile Dry and Wet Machining Bur Machine:

- Equipped with 5 axes.

- It features an automatic 8-disc changer that takes care of material handling.

- The system chooses and inserts the appropriate disc for each restoration.

- Capable of non-stop machining without user intervention.

- Maximum precision, non-stop performance and reliability.

- High dust protection.

- Safeworking space .

- Light in the working chamber.

- Easy to place in any corner of the dental laboratory.

Description

Dry Bur and Grinding Machine (5-axis) Pro Expert 5

The Pro Expert 5 Bur Machine is able to mill and grind 24 hours a day non-stop, without the need for any operation steps. It is highly accurate and stable, capable of processing all types of materials, including CoCr, titanium and glass ceramics. Contains 3 ionisers that neutralise the static charge of the acrylic chips, for a clean working chamber.

Features of the Bur Machine:

- Automatic changer system for 8 discs, 24 blocks or 48 prefabricated pillars that manages the materials.

- Able to choose and insert the right disc for each ultra HD restoration without user intervention.

- It has a premium needle with precision bearing.

- Solid cast body for minimum vibration.

- Almost unlimited accessibility of material in 98 mm disc format, as well as 38 block materials and more than 800 prefabricated titanium and CoCr raw abutments.

- Wide range of indications due to ± 30° rotation angle in the fifth axis and blanks up to 30 mm.

- Automatic tool changer for 16 tools.

- Easy to operate using the DentalCAM software (high performance) with open STL import for all common CAD programs and DirecMill function included.

- With optimised CAM strategies for the fastest possible machining.

Technical specifications:

- Fields of application: Wet and dry milling option.

- Weight: one 95 Kg.

- Dimensions: 692 x 445 x 540 mm.

- Automatic charger: 8 blanks, 24 blocks or 48 preloaded.

- Automatic tool changer: 16 tools.

- Machinable materials: Zirconia, Wax, PMMA, CoCr, Peek, Acetal, Titane, Premoulded, Nanoceramic, Feldspar.

- With option of 3 dry blocks: Lithium disilicate, Composite resin, Lithium silicate.

- File format: STL.

- Number of axles: 5.

- Rotation speed: up to 60,000 rpm.

- Power: 600 W

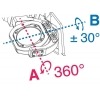

- Positioning range: A 360° rotating shaft degrees B rotary axis (fifth axis) of ± 30 degrees Engrenage Harmonic Drive.

- Repeat accuracy: ± 0,003 microns.

- Air consumption: Minimum 7 bar - 80 L / min.

- With option of 3 dry blocks.

- With built-in ioniser.

- With tool-free blank clamping system.

Questions and answers

There are no questions yet. Be the first to ask one!

You need to be logged in to ask questions. Login