Dental plasters are materials commonly used in dentistry, especially in the laboratory when creating models for prostheses or coatings for casts.

Looking for a complete overview of dental casts and plasters? Stay right here! In this article, we will tell you what these materials are used for, their classification, applications and very interesting facts that you're sure to find useful. Don't miss it because we're getting started!

Plaster is a mineral obtained from a natural reserve, a type of sedimentary rock composed of calcium phosphate formed in areas where sulphuric acid is in action on calcium minerals. To obtain dental casts or plasters, this material undergoes a calcination process at around 120ºC and is then mixed with water for its correct setting, obtaining a dehydrated calcium sulphate stone.

Classification of dental plasters

Now, let's tell you about the classification of dental plasters according to the ADA (American Dental Association), as the manufacturers of this material are guided by these regulations. Don't miss it! We will also show you examples of each of them.

➜ Impression plaster (Type I)

It is a compound of plaster of Paris (dry white powder) with some components used to regulate setting and expansion. Nowadays it is practically unusable because it is weak and porous.

➜Modelling plaster (Type II)

The Type II dental plaster is the most commonly used in laboratories:

- Models.

- Diagnostic models for orthodontics.

- Mounting of models in the articulator.

- Filling of acrylic dentures.

Fast setting plaster Snow White Type II

Snow White is a fast setting type II dental plaster for impressions, articulation, creation of temporary teeth or labial/occlusal guides. Main features:

- Easy on the eye

- Pastel shades for easy reading.

- It is an option for all types of dental techniques.

- Available in 4.5 or 20 kg.

➜Dental plaster (Type III)

Type III dental plaster is stronger and is used for:

- Construction of models in the fabrication of partial or full dentures.

- Diagnostic models, antagonist models and removable prostheses.

Ventura Stone Hard Type III Plaster

This type III dental is suitable for removable full or partial dentures, antagonist models and models for skeletons:

- Compatible with all impression materials.

- High density.

- Smooth surfaces with optimal detail reproduction.

- Available in blue or yellow (5 kg).

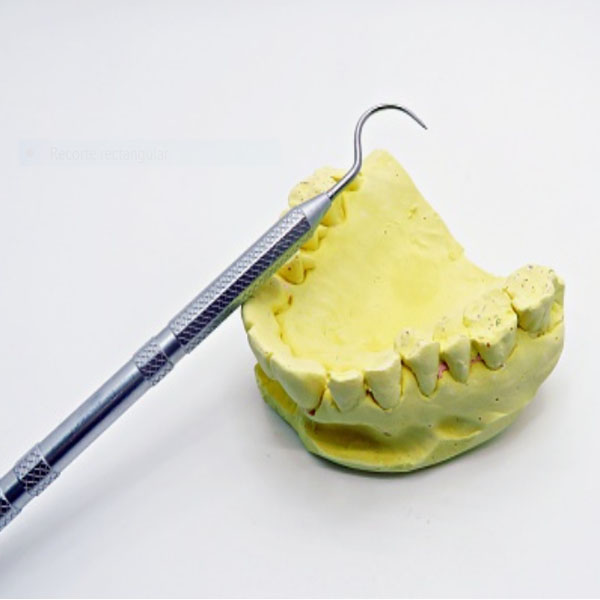

➜High strength dental plaster (Type IV)

This type of dental plaster is characterised by its strength, low expansion and hardening. Its mixture is not fully thickened and is resistant to abrasion. It is a plaster for working dies on which dental rehabilitation work such as crowns, implants, posts or prostheses is carried out.

Ventura SuperDie Rock Type IV Extra-Hard Plaster

Scannable plaster type IV perfect for precise work such as the construction of models for bridges and crowns, inlays and removable dies:

- Light vibration and high fluidity

- Compatible with all impression materials. Available in golden brown, grey or white (6 kg).

➜High-strength plaster (Type V)

The newest dental plaster! It has high compressive strength (more than type IV). Must be abrasion resistant with minimal set expansion. They are used to balance the crystallisation shrinkage of high melting alloys or shrinking materials.

Dental plaster designations and applications: beta, alpha 1 and alpha 2

What are the differences between the types of dental casts? For example the size, shape and porosity of the calcium sulphate crystals. For this reason the type of plaster will influence the amount of water to be used when mixing each one.

- Beta dental plaster: known as white plaster, it is the least resistant but least expensive plaster. It is used for plaster casts, model bases and set-ups.

- Alpha 1 dental plaster: characterised by its hardness and dimensional accuracy. It is used for some restorations, study and diagnostic models.

- Alpha 2 dental plaster: used when high precision and strength are required: prosthetic work and for orthodontic models.

Chemical properties of dental plaster

- Setting: this is the step from hemihydrate to dihydrate. As plaster is obtained from calcination, it reacts with water to form plaster to varying degrees.

- Water requirement: the density of the powder is responsible for the water requirement of the different types of plaster.

- Setting speed: water and powder are closely related in the setting speed, as a dental plaster mixture with a low water to powder ratio will become a hardened mixture more quickly because the nucleation centres are concentrated with low volume.

- Setting expansion: the higher the amount of water, the lower the setting expansion.

Physical properties of dental plasters

- Compressive strength wet or dry.

- Abrasion resistance.

- Fractional strength.

⚠️What factors must be taken into account to mix the plaster correctly?

- Water to plaster ratio: it is important to understand that the more water, the lower the number of crystallisation nuclei. What does this mean? Longer setting time.

- Spatulate: the more spatulate, the higher the number of crystallisation nuclei and the shorter the setting time.

- Water temperature: low temperatures are synonymous with shorter setting time, while temperatures above 37º means longer setting time. What happens when the temperature is above 90º? There is no setting time because at such a high temperature the powder is dehydrated.

- Pouring technique: how is plaster prepared?, we'll tell you! First, the plaster must be vibrated to remove bubbles and improve the strength. Then pour the plaster in the highest area and finally fill in the plaster without going over the edge.

Water/powder ratio

This proportion should be measured as indicated by the manufacturer in each case, but we are going to tell you what the recommended proportions are depending on the type of plaster!

First, the powder should be weighed on a scale and the water should be measured with a graduated cylinder:

- Type I Dental plaster➜ 100g/40-75 ml.

- Type II Dental plaster➜ 100g/40-50 ml.

- Type III Dental plaster➜ 100g/30 ml.

- Type IV Dental plaster➜ 100g/23 ml.

- Type V Dental plaster➜ 100g/18-22 ml.

Two top tips to keep in mind when proportioning is to follow the manufacturer's instructions and to be aware that variations in water/powder affect the strength or accuracy of the setting material.

This is the end of our article on dental plasters and casts! Remember that at Dentaltix we have a wide variety of dental casts available that are sure to perfectly meet your needs.

We hope you liked it and don't miss our social networks where we tell you about the best news in the dental sector each week. We hope to see you soon in the next article!