Modern dentistry has advanced greatly thanks to innovative technology and materials, allowing for high-quality results in every procedure. Among the most essential tools for achieving these results are dental polishing discs, which are fundamental for providing aesthetic and functional finishes in dental restorations. These discs have evolved alongside technology, allowing dentists to achieve a level of perfection that was previously unthinkable. Their ability to remove irregularities and achieve smooth, shiny surfaces has established them as essential tools in the field of dentistry.

The use of polishing discs not only improves the aesthetics of restorations, but also plays a crucial role in the structural integrity and durability of treatments. In this article, we will explore in detail the characteristics that make polishing discs an indispensable tool, their applications in dental procedures, and the advantages they offer to both professionals and patients.

What Are Dental Polishing Discs?

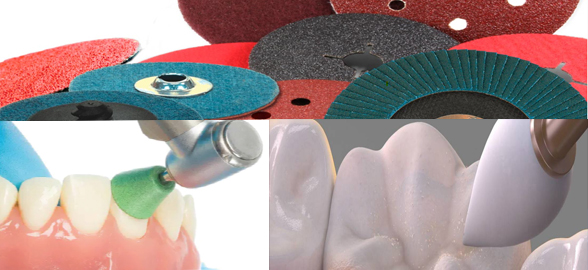

Dental polishing discs are essential rotary instruments in the dental field, specifically designed to optimise the quality and aesthetics of dental restorations. Manufactured with high-precision abrasive materials, these tools allow for a wide range of procedures, from removing excess material to refinement and final polishing, achieving smooth, shiny surfaces that are completely integrated with the natural tooth structure.

Thanks to their variety of sizes, thicknesses and levels of abrasiveness, polishing discs offer versatility and adaptability for each stage of treatment, facilitating personalised results according to the specific needs of each patient. Their use not only improves the functionality and appearance of restorations, but also contributes to the prevention of future problems, such as the accumulation of bacterial plaque.

Common Uses of Polishing Discs

The discs are used for the following treatments:

- Composite Resin Restorations: Polishing discs are essential for perfecting restorations made with composite resins. They help remove excess material, smooth the surface, and achieve a natural finish that resembles tooth enamel.

- Polishing Ceramics and Porcelain: On crowns, veneers, and other ceramic restorations, polishing discs smooth the surface, providing a glossy finish that mimics the texture of natural teeth.

- Working with Metallic Materials: They are useful for cleaning and smoothing metallic surfaces, such as denture bases or metal crowns, ensuring greater comfort for the patient.

- Removal of Stains and Deposits: The discs allow for the cleaning of restorations that have accumulated stains or plaque without damaging the materials, restoring their original appearance.

- Occlusal Adjustment: In cases where adjustments are needed in the contact areas with the opposing teeth, polishing discs remove small irregularities and ensure precise and functional occlusion.

Types of Polishing Discs According to Materials and Function

The dental market offers a variety of polishing discs that differ in design, composition, and specific application.

- Silicon Carbide Discs: These discs have medium abrasiveness and are ideal for removing material and creating a smooth surface. They are widely used in composite resin restoration and are recommended for use in the initial stages of polishing.

- Aluminium Oxide Discs: This type of disc is characterised by its high wear resistance and its ability to perform fine, detailed polishing. They are perfect for ceramic or metal restorations and are used in the final stages of polishing to give the restoration a shine.

- Diamond discs: Diamond discs are especially useful when very high abrasiveness is required. These discs are perfect for working on porcelain or hard metals and are used in restorations where extreme precision is required, such as ceramic crowns or veneers.

- Resin discs: These are designed for polishing restorations made with resin composite materials. Resin is characterised by being a more flexible material and, therefore, resin discs have a softer structure than aluminium oxide or silicon carbide discs, which helps to prevent damage to the restoration.

- Rubber discs: Made from a mixture of rubber and abrasives, these discs are ideal for final polishing and shining. They are mainly used on metal and ceramic restorations to give them a final shine.

Distinctive Features of Dental Polishing Discs

The distinctive features of the discs are:

- High-Quality Abrasive Materials: Dental polishing discs are made from high-quality abrasive materials, such as silicon carbide, aluminium oxide, diamond or synthetic resins, which allow for controlled polishing without damaging the surface of the restoration. In addition, these discs are available in a variety of textures and colours, making it easy to choose according to the desired finish: from more intense abrasion with coarse discs to fine, shiny polishing with softer discs.

- Flexible Composition: The flexibility of polishing discs is another important feature. Many discs are made from a flexible base that allows them to adapt to the shape of dental surfaces, making them more effective in achieving more precise and personalised results.

- Various Sizes and Shapes: Polishing discs are available in various sizes and shapes (circular, semi-circular, conical) to suit different areas and types of dental restorations.

- High Durability: Dental polishing discs are highly resistant tools that, despite constant use, maintain their effectiveness and do not lose their abrasiveness quickly.

Take a look at the best-selling polishing discs:

How to Choose the Ideal Polishing Disc?

Choosing the right polishing disc depends on several factors, such as the material to be polished, the stage of treatment the restoration is at, and the type of finish you want to achieve. Below, we will detail the most important aspects to consider.

Identify the Restoration Material

It is essential to select the disc based on the type of material being worked on, as not all discs are compatible with all surfaces.

- Hard materials (such as ceramics and metal): For ceramic, metal or zirconium restorations, silicon carbide or diamond-coated discs are the most effective, as they offer the strength and precision required to work with these materials.

- Soft materials (such as composite resins): Aluminium oxide or resin discs are ideal for softer materials, such as composite resins, as they allow for careful polishing without damaging the surface.

Consideration of the Procedure Phase

The polishing process is divided into several stages, each requiring a specific type of disc.

- Initial Stage: In this phase, where excess material is removed and the restoration is shaped, highly abrasive discs should be used. These discs allow you to work quickly and efficiently to shape the restoration according to clinical requirements.

- Intermediate and Final Stages: As you progress towards the final finish, it is crucial to switch to medium or fine abrasive discs to perfect the surface and remove any imperfections. Finally, ultra-fine discs are essential for achieving a smooth, shiny finish that simulates natural enamel.

Defining the Desired Finish Type

Depending on the desired aesthetic and functional result, the choice of polishing disc may vary.

- For Exceptional Shine: Ultra-fine or diamond-coated discs are the best option for achieving a natural shine that perfectly mimics the appearance of the original tooth. They are especially useful in anterior restorations where aesthetics are a priority.

- For Material Removal: In cases where the priority is to remove material rather than achieve a shiny finish (e.g., in the initial reduction of a restoration), thicker, more abrasive discs are more suitable.

Disc Size and Flexibility

In addition to composition and abrasiveness, it is also important to consider the size and flexibility of the disc.

- Smaller discs are ideal for hard-to-reach areas or fine details.

- Flexible discs adapt to the anatomy of the tooth, facilitating a uniform finish even on curved surfaces.

Ensure that the polishing disc is compatible with the rotary system you are using. Some discs are designed to operate at specific speeds, and using them outside of these recommendations may compromise both the outcome and the safety of the procedure.

Guide to Identifying the Characteristics of Polishing Discs .

On our website, you will find a detailed description of each characteristic of the polishing discs, organised clearly to facilitate your search. Below, we explain how to identify each attribute:

- No. (Number): Identifies the specific model or reference of the disc, so you can choose the most suitable one for your needs.

- F (Shape): Indicates the shape of the disc, such as flat, conical or curved, adapting to different areas and clinical procedures.

- Du (Hardness): Defines the level of rigidity of the disc, ideal for selecting the desired pressure and degree of abrasion.

- I (Instrument): Specifies the type of tool with which the disc is compatible, ensuring its correct operation.

- Di (Diameter): Indicates the size of the disc, allowing you to choose from options that fit different tooth surfaces.

- H (Height): Shows the thickness or profile of the disc, which is key for procedures with limited space.

- M (Material): Describes the composition of the disc, such as aluminium oxide, silicon carbide or other materials, which are essential for its performance.

Benefits of Using Polishing Discs in Dental Aesthetics and Functionality

Proper use of polishing discs improves dental aesthetics, prolongs the life of restorations, and promotes integration with natural teeth, optimising both functionality and patient comfort.

- Optimisation of Dental Aesthetics: One of the main benefits of polishing discs is their ability to achieve a flawless aesthetic finish. Thanks to their design, they allow for restorations with a natural shine and smooth surface, more accurately simulating the appearance of a healthy tooth. This not only improves the overall appearance of the restoration, but also contributes to the patient's confidence in their smile.

- Extending the Life of Restorations: Proper polishing is key to extending the durability of restorations. By removing sharp edges, microcracks, and rough surfaces, plaque and debris accumulation is reduced, factors that could compromise the restoration over time. This not only ensures better functional performance, but also minimises the need for premature adjustments or replacements.

- Harmonious Integration with the Natural Tooth: Polishing discs allow for a virtually imperceptible transition between the restoration and the natural tooth. This smooth finish not only improves aesthetics, but also protects the gums by avoiding abrasive areas that could cause irritation or discomfort. Precise adaptation contributes to a proper seal, reducing the risk of leakage.

- Reduced Risks and Complications: The use of high-quality polishing discs minimises the risk of injury to surrounding soft tissues, such as the gums, and prevents unwanted wear on adjacent teeth. A precise finish also reduces the possibility of fractures in restorations, contributing to the overall safety of the procedure.

- Improved Functionality and Patient Comfort: By smoothing the surfaces of restorations, polishing discs ensure that the patient experiences less friction during chewing, increasing their comfort. In addition, by reducing rough areas, the risk of food accumulation is decreased, contributing to better oral hygiene.

- Increased Patient Satisfaction: The results of a well-executed procedure, characterised by shiny, smooth and highly functional restorations, create a positive impression on the patient. The combination of aesthetics and comfort reinforces the perception of a successful treatment, which in turn strengthens the relationship of trust between the professional and the patient.

Understanding the characteristics, different types available, and applications of polishing discs, as well as the benefits they provide to patients, is essential for selecting the most appropriate tools for each procedure. In a dental practice, offering these high-quality discs is not only a way to ensure the success of treatments, but also a way to guarantee customer and patient satisfaction.

That concludes our article for today. As always, we are very grateful that you are a loyal reader and we appreciate your interest in our content. If you would like to continue reading, we invite you to follow us on our social media channels. Please also contact us with any suggestions or questions you may have, as we are always happy to help. See you next time!